Created with

the key concept of “kindness”, educational toys that are close to people and the environment

Poco a poco is shaped by three thoughts: “environmentally friendly,” “gentle to the heart,” and “delivering excellent products.”

With these thoughts in mind,the gentle educational toys “Nijiiro series” were born.

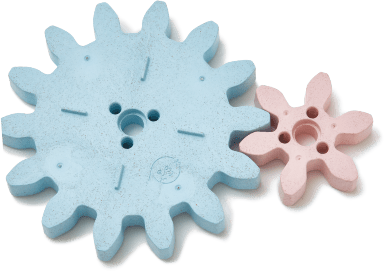

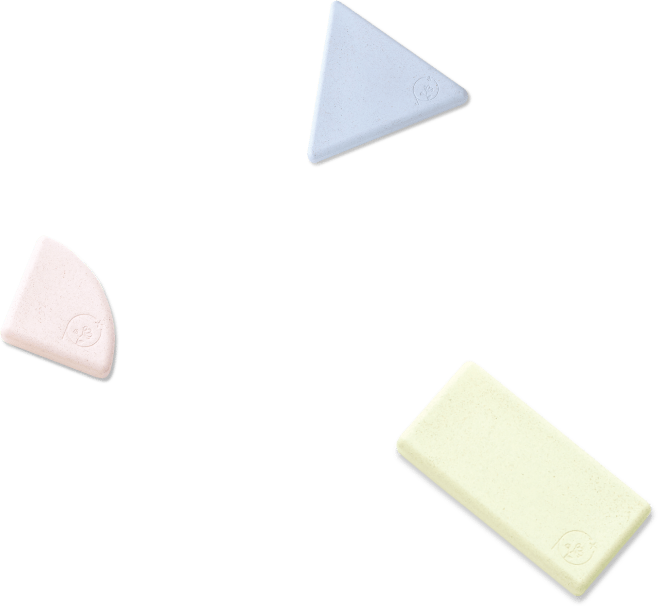

The material used is “rice husk resin,” an eco-friendly bioplastic made mainly from rice husks removed during the process of turning harvested rice into edible rice. Our educational toys, that everyone can enjoy, are not only made with natural

materials but also carry our best wishes for the future in the shape of carefully selected sizes, textures, colors and attention to safety.

The “Nijiiro Series” not only activates the brain because you move your hands and fingers a lot when you play, but you can also enjoy experiencing a range of elements such as “shapes”, “numbers”, “words”, and “spatial awareness” while in play.

Poco a poco holds these kindnesses

dear, and walks with those who

share the same ideals, towards a

future that mbraces them.

What is Poco a Poco?

It is a musical term “little by little”.

“Poco a poco” is a musical term that means “little by little”. Moving towards a future full of joyful and bright smiles, we want children to accumulate various experiences steadily and grow little by little.

An eco-friendly

material

derived from “Rice husks”

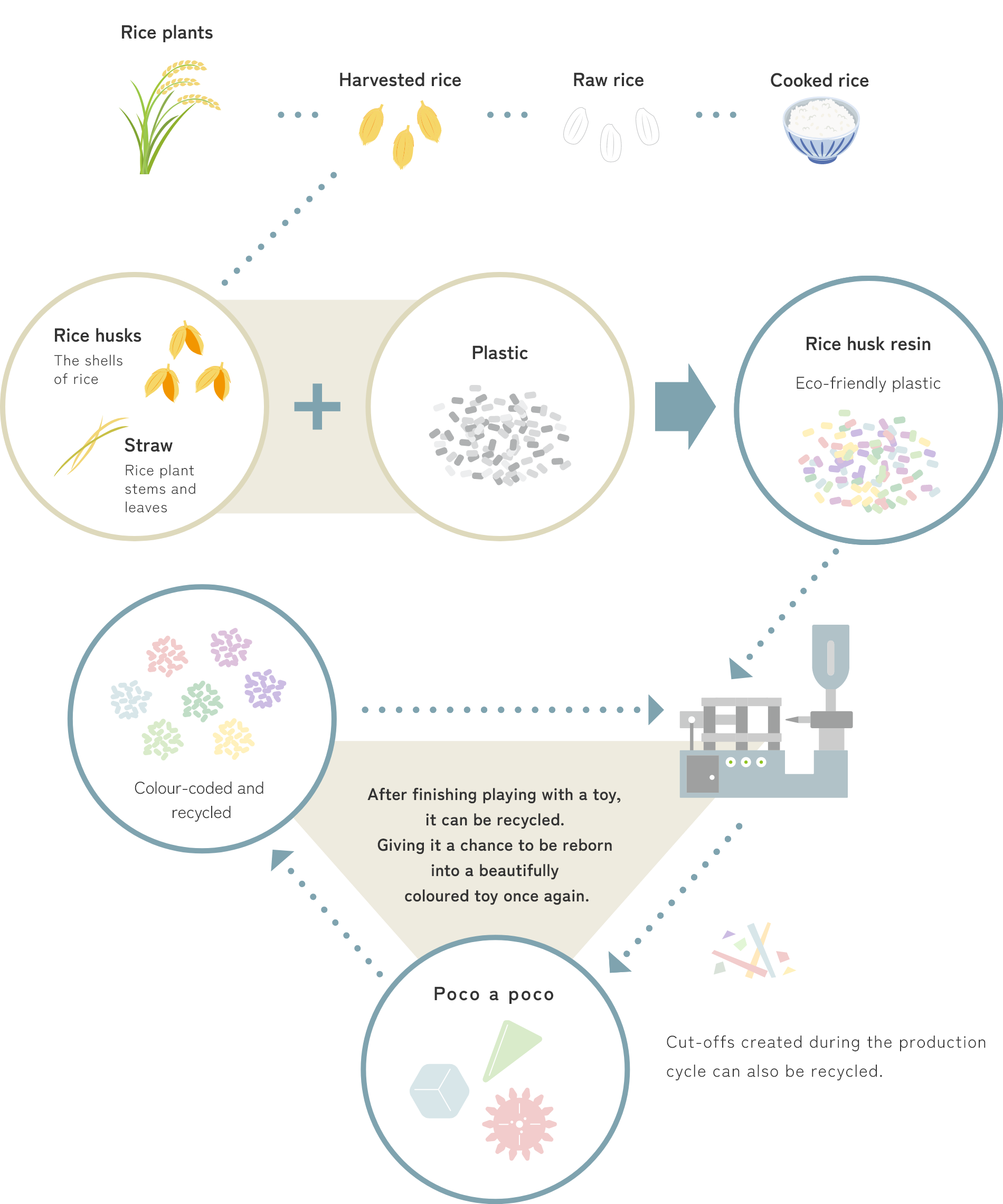

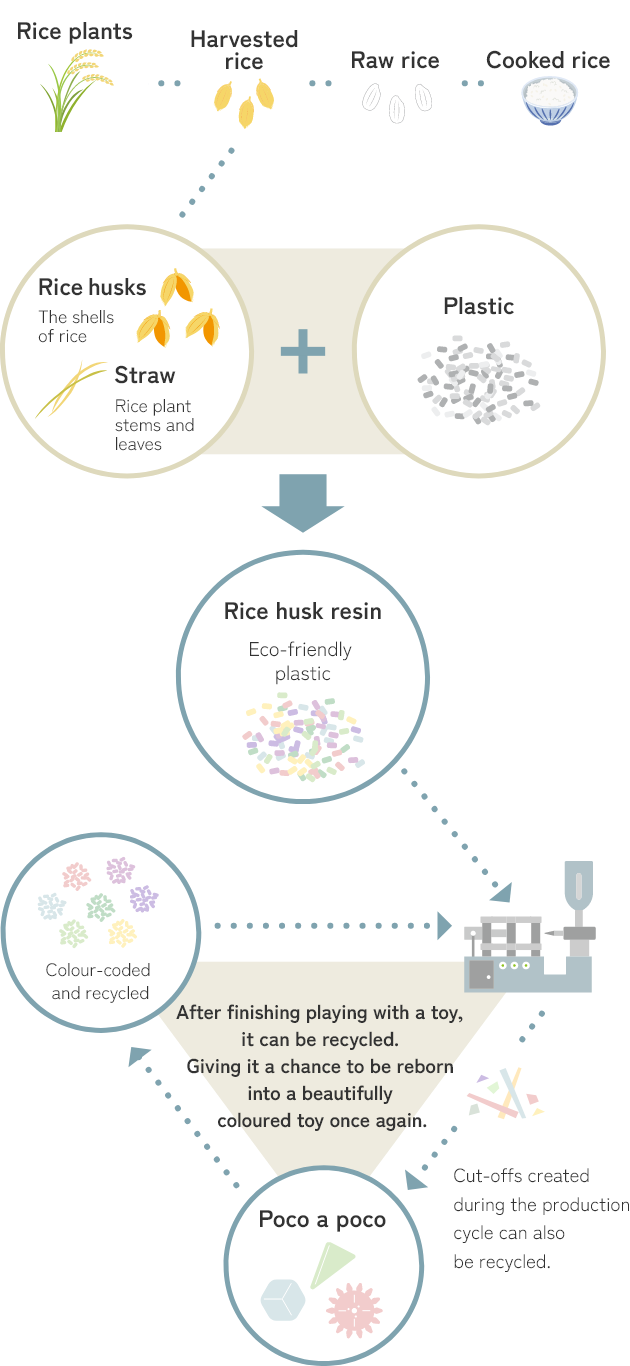

Rice husks, the outer layer of rice removed from harvested rice during the process of turning it into edible rice. In Japan, the large amount of rice husks produced during the harvesting process are beginning to be reused in a variety of settings.

Poco a poco toys are made from rice husk resin, an eco-friendly bioplastic with rice husks as the main raw material.

In addition to making effective use of rice husks that would otherwise be discarded, Poco a poco contributes to the reduction of environmental burdens by recycling scrap materials from the manufacturing and toys that are no longer in use.

Poco a poco material (Flow-chart)

Toy safetyThoroughly committed to safety

Safe size and design to

prevent accidental ingestion

Even if a child accidentally puts a toy in their mouth, they are designed to be large enough not to be swallowed. We use inspection equipment stipulated by the Japan Toy Association to check that the size of all toy parts meets the standards. Our toys also bear the CE mark, which means we meet the safety standards required for export to the EU. As for the shape, the design has rounded corners so that it fits comfortably in a child’s hand. You can use it with confidence.

Safe for all, materials

Toys always find their way into our little ones’ mouths. Therefore, they must be safe. We ensure this by inspecting them for the absence of heavy metals (lead, arsenic, cadmium, etc.) and harmful colourants. The “Nijiiro Series” meets European standards that are stricter than Japan.

Robust structural designs

are in our nature

All our toys undertake mechanical safety testing. The toys are subjected to tests, such as pressure, tension, and dropping. Sturdy structual design and assembly that can pass these tests are strengths of Poco a poco, whose parent company is a plastics manufacturer.

Alcohol resistant and

hygienically safe

The “Nijiiro Series” is made of an alcohol-resistant plastic material and plant-derived rice husks. Due to the materirals used it is less likely to deteriorate due to alcohol. A third-party organization checks the resistance by immersing it in high-concentration ethanol (80%) and conducting a chemical property inspection to check for damage or discoloration after 1 hour. For example, if a material is sensitive to alcohol, it will crack or lose its colour, but the “Nijiiro Series” is made of alcohol-resistant bio-plastic, so you don’t have to worry about that. In other words, even if you disinfect with alcohol every day, the material will not deteriorate, so it is safe and secure in terms of hygiene.

About us

Poco a poco is a brand of educational toys that is planned, developed, manufactured, and sold by “Sanyu Raito Industry Co., Ltd.” Sanyu Raito’s main business is injection molding and mold manufacturing of precision parts for the plastic industry and industrial industry. They manufacture industrial parts required in a wide range of scenes and bicycle parts that are used around the world. Using this expertise in plastic products, we are giving shape to an exciting future for everyone.